Sustainable and green electronics for circular economy

OVERVIEW

The main goal of the Sustronics project is to transform the European electronics industry by harnessing the power of sustainable practices and fostering innovation. By combining eco-friendly electronics, increased productivity, and the development of cutting-edge functionalities, the project aims to propel the industry towards a more sustainable and prosperous future. With a strong focus on green technology and novel business opportunities, Sustronics seeks to make a lasting impact on the electronics landscape in Europe.

Sustronics’ ambition is to become ‘the’ European flagship project for sustainable electronics by building an ecosystem to demonstrate how the electronics industry can benefit from:

- sustainable materials

- sustainable manufacturing

- Eco-design

- energy efficient products

- circular business models

Sustronics brings the whole sector closer to meeting Green Deal objectives while at the same time improving electronics industry’s competitiveness and strategic autonomy

OBJECTIVES

1: Improve resource sufficiency by benefitting from ecodesign targets

To improve resource sufficiency by benefitting from ecodesign targets to replace fossil-based materials with bio-based and abundant materials, to decrease use of resources (e.g. energy), to benefit from circular and modular design concepts, and to introduce sustainable manufacturing concepts compatible with novel materials.

2: Develop electronic functionalities, components, devices and software with sustainable approaches

To develop electronic functionalities, components, devices and software with sustainable approaches without compromises in performance by benefiting from:

- sustainable materials and manufacturing technologies,

- design for circularity and minimized environmental impact,

- environmentally compatible end-of-life management strategies,

- low-power technologies,

- AI technologies.

The main components to be developed include sensors and sensor platforms, printed electrodes, power sources, photonic components, chips, and software functionalities targeted for energy efficiency.

3: Integrate pilots covering the product lifecycle and value chain in different sectors

To integrate and analyse pilots covering the product lifecycle and value chain in different sectors, more specifically health monitoring, diagnostics, medical and personal health devices, automotive and lighting, focusing on three use cases that all benefit from digitalization, ecodesign, circular design, sustainable materials, and energy efficiency, with three pilots each:

- ‘circular electronic devices’ with three pilots,

- ‘sustainable manufacturing for electronics’ with three pilots,

- ‘environmentally compatible single-use electronics’ with three pilots.

4: Quantify sustainability of the developed solutions, including environmental, societal and economic impact

To quantify sustainability of the developed solutions, including environmental, societal and economic impact, and use this data to guide development of materials, technologies, and pilots. This will also include development of new tools to better use lifecycle data to support decision making during product design and manufacturing phase.

5: Specify end-of-life management concepts for circular and compostable electronics

To specify end-of-life management concepts for circular and compostable electronics, and to provide means for making end-of-life management more efficient, e.g. introduction of digital product passport concept and new recycling methodologies tailored for sustainable products enabling improvements to component disintegration and material recovery.

6: Commit stakeholders to sustainability approach and increase business opportunities

To implement a community engagement strategy targeting to change stakeholder attitudes towards sustainability as a business and market approach, and creating new business opportunities by:

- involving stakeholders among industry and citizens for co-creation and validation,

- actively communicating with external stakeholders during various engagement activities, such as participation to events and organization of project workshops,

- developing a blueprint for policy outreach to guarantee compatibility with existing and emerging legislation and standards.

USE CASES

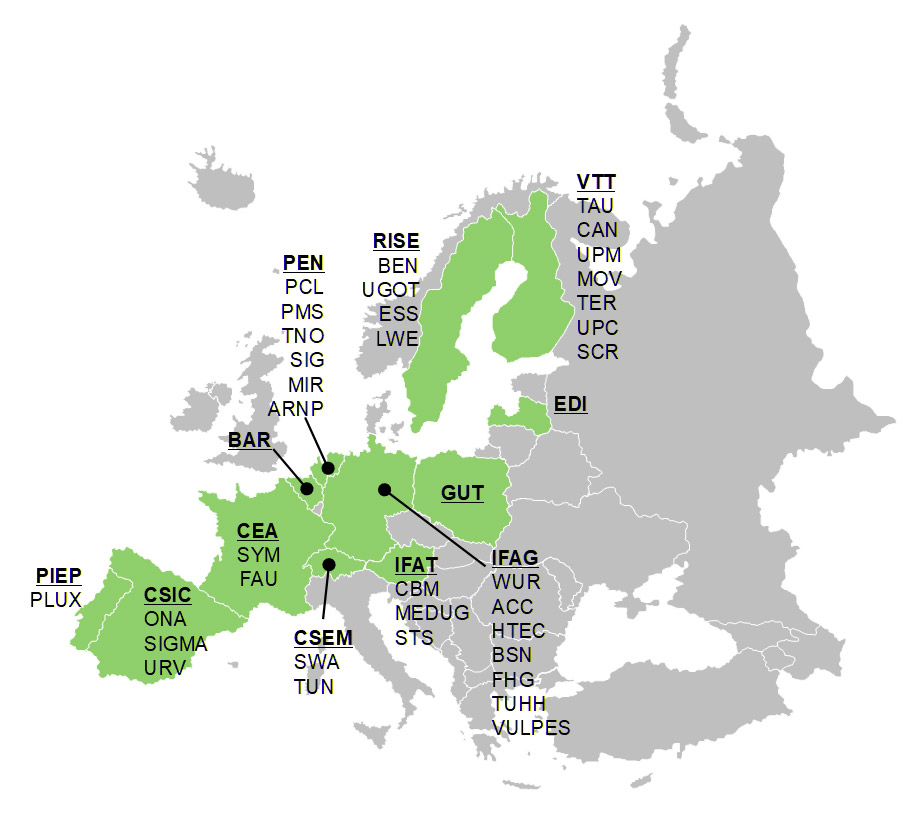

CONSORTIUM

46 Partners

Combination of large enterprises, SMEs, research organizations and universities throughout the electronics value chain & life cycle

11 countries

Austria, Finland, France, Germany, Latvia, Netherlands, Poland, Portugal, Sweden, Spain, Switzerland

NEWS & EVENTS

Open Access Policy

More information soon.